Difference between revisions of "Screenshots and videos"

From Yade

m (→Videos: added short explanation to videos.) |

|||

| (41 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | If you are working with yade, please upload some of your screenshots to show others your work! |

|

| + | =Videos= |

||

| + | If you click on one of the following links, you will be redirected to a page that contains the videos: |

||

| + | * [[Outflows | Outflows]] |

||

| + | * [[Ball mill | Ball mill]] |

||

| + | * [[Representing_surfaces_beams_wires | Representing surfaces beams wires]] |

||

| + | * [[Fluid-solid_coupling | Fluid-solid coupling]] |

||

| + | * [[Processing_machines | Processing machines]] |

||

| + | * [[Miscellaneous_videos | Miscellaneous videos]] |

||

=Screenshots= |

=Screenshots= |

||

| Line 9: | Line 17: | ||

{{clr}} |

{{clr}} |

||

| − | ==[[Scr:Discrete Element Method|Discrete Element Method]]== |

||

| − | [[Image:scr_dem_thumb.png|right]] |

||

| − | A first real-world application of Spherical Discrete Element Method is implemented, with a catchy name Yade OpenDEM. Handles shearing forces between spheres, cohesive forces with modified mohr-coulomb criterion. This is a reimplementation from ground-up of SDEC program, which has been used for over ten years in University of Joseph Fourier in Grenoble, and many PhDs were done with it. |

||

| + | ==Jointed/Fractured Media== |

||

| − | [[Scr:Discrete Element Method|more >>]] |

||

| + | YADE can be used to model media containing pre-existing fractures/discontinuities. The module was initially developed for the study of fractured rock masses as described in refs [1], [2] and [3]. |

||

| − | {{clr}} |

||

| + | [[Image:DEMDFN.jpg|600px]] |

||

| − | ==[[Scr:DEM with local moment law|Discrete Element Method with Local Moment Law]]== |

||

| − | [[Image:scr_mdem_thumb.png|right]] |

||

| − | Discrete Element Method has been extended with law of conversion of momentum at the contact point. Resulting in a complete model for simulations of spherical elements. This has opened new broad variety of model applications, including deformable non-rigid body simulations, concrete and steel modelling. And later - after yade will have non linear models implemented - other kinds of plastic, viscoplastic, elastoplastic behaviours using spherical elements. |

||

| + | Discrete fracture network (DFN) can be imported as meshed surfaces and embeded into a predefined intact medium consisting of bonded particles. Interactions located across a discontinuity surface are identified and their behavior can be adjusted according to the user's choice (cohesive, frictional,...). An option provides the possibility to orientate the contact geometry in agreement with the discontinuity surface to get rid of the particle shape (for more details, see refs [1], [2] and [3]). An example showing how to use this module is provided in example/jointedCohesiveFrictionalPM/ |

||

| − | [[Scr:DEM with local moment law|more >>]] |

||

| + | |||

| + | [1] http://dx.doi.org/10.1016/j.jmps.2011.01.009 |

||

| + | |||

| + | [2] http://dx.doi.org/10.1016/j.ijrmms.2012.02.009 |

||

| + | |||

| + | [3] http://dx.doi.org/10.1111/j.1365-246X.2012.05642.x |

||

{{clr}} |

{{clr}} |

||

| − | |||

==[[Scr:Other|Other]]== |

==[[Scr:Other|Other]]== |

||

[[Image:scr_other_thumb.png|right]] |

[[Image:scr_other_thumb.png|right]] |

||

| − | Yade is now good enough to produce some results. Those results are at first compared with results from other numerical computations software, then with real-world experiments. Several articles are planned to be written about it. For now you can have a short glance at what kind of results we can produce so far. Bear in mind that this is just a quick look at screenshots and nothing more. |

+ | Yade is now (2007) good enough to produce some results. Those results are at first compared with results from other numerical computations software, then with real-world experiments. Several articles are planned to be written about it. For now you can have a short glance at what kind of results we can produce so far. Bear in mind that this is just a quick look at screenshots and nothing more. |

[[Scr:Other|more >>]] |

[[Scr:Other|more >>]] |

||

| − | {{clr}} |

||

| − | |||

| − | =Videos= |

||

| − | |||

| − | == Rectangular outflow == |

||

| − | |||

| − | {{#evp:youtube|fyKqaqjx1uQ}} |

||

| − | |||

| − | Simulation of a granular outflow from rectangular hopper. You can see the funnel and wall layer. |

||

| − | |||

| − | == Rectangular outflow frictionless == |

||

| − | |||

| − | {{#evp:youtube|x4AGNc6hxAY}} |

||

| − | |||

| − | Simulation of a outflow frictionless particles from rectangular hopper. Color denotes a local free volume. Seen an increase in free volume in the regions of shear flow due to the effect of dilatancy. |

||

| − | |||

| − | == Rectangular outflow: frictional VS frictionless walls == |

||

| − | |||

| − | {{#evp:youtube|OHJdGXQ2Yis}} |

||

| − | |||

| − | Simulation of a granular outflow from rectangular hopper. Front and back walls is frictional (right two) and frictionless (left two). You can see different flows pattern. |

||

| − | |||

| − | == Cylinder outflow == |

||

| − | |||

| − | {{#evp:youtube|ey0_jzyrsxU}} |

||

| − | |||

| − | Simulation of a granular outflow from a cylindrical hopper with flat bottom. |

||

| − | |||

| − | == Cylinder outflow: local volume of solid == |

||

| − | |||

| − | {{#evp:youtube|tFiMGciM5dY}} |

||

| − | |||

| − | Simulation of a granular outflow from a cylindrical hopper with flat bottom. Particles are colored by local volume of solid. You can see the rarefaction in the shear flow region at bottom of the cylinder due to dilatancy. |

||

| − | |||

| − | == Cylinder outflow: conical bottom == |

||

| − | |||

| − | {{#evp:youtube|aNnZoo3x9S0}} |

||

| − | |||

| − | Simulation of a granular outflow from a cylindrical hopper with conical bottom |

||

| − | |||

| − | == Hoppers jamming == |

||

| − | |||

| − | {{#evp:youtube|fPpdBKhx84o}} |

||

| − | |||

| − | How granular materials jam in a hopper. The simulation is inspired by experimental work of J.Tang and R.P. Behringer http://youtu.be/lWSJwZhqoQw |

||

| − | |||

| − | |||

| − | == Ball Mill 2 == |

||

| − | |||

| − | {{#evp:youtube|pfQpnxDSbqQ}} |

||

| − | |||

| − | A sample of simulation of movement of 125 000 spheres with YADE. |

||

| − | This simulation take 14h30m for 50 000 iterations on laptop with Intel(R) Core(TM)2 Duo CPU T8100 @ 2.10GHz processor and 2GB memory. So, perfomance was 0.95 iter/sec. |

||

| − | |||

| − | See yade script [http://bazaar.launchpad.net/~yade-dev/yade/trunk/annotate/2099/examples/STLImporterTest.py here] (it need this [http://bazaar.launchpad.net/%7Eyade-dev/yade/trunk/download/svn-v4%3A02f7d466-02ed-0310-b97e-c604c3e52537%3Atrunk%3A1353/1353%4002f7d466-02ed-0310-b97e-c604c3e52537%3Atrunk%252Fexamples%252Fbaraban.stl/baraban.stl stl-file] for the mill shape.) |

||

| − | {{clr}} |

||

| − | |||

| − | == Ball Mill == |

||

| − | {{#evp:youtube|KUv26xlh89I}} See [http://bazaar.launchpad.net/~yade-dev/yade/trunk/annotate/1743/examples/mill.py yade script]. The mill shape is constructed parametrically from within the script itself. |

||

| − | {{clr}} |

||

| − | |||

| − | == Surface triangulation and filling == |

||

| − | {{#evp:youtube|PZVruIlUX1A}} Sphere packing (regular) is generated to fit inside the horse-shaped triangulated surface (imported from file). The same horse is the used underneath, on which the spheres fall from above. Script is [http://bazaar.launchpad.net/~yade-dev/yade/trunk/annotate/1744/scripts/test/gts-horse.py here] |

||

| − | {{clr}} |

||

| − | |||

| − | == Representing beams and wires with connected cylinders == |

||

| − | {{#evp:youtube|iGHBb3nzOx0}} Connected cylinders with rounded ends (alternatively seen as Minkowski sum of a polyline and a sphere enables the description of interaction between wires or rods and particles, with a smooth interface. The simulation is defined in [http://bazaar.launchpad.net/~yade-dev/yade/trunk/annotate/head%3A/scripts/test/chained-cylinder-roots.py this script]. |

||

| − | |||

| − | ==Discrete Element Method - 125 000 spheres== |

||

| − | [[Image:dem 125k thumb.png|right]] |

||

| − | As first real-world application of yade Spherical Discrete Element Method is implemented. Handles shearing forces between spheres, cohesive forces with modified mohr-coulomb criterion. |

||

| − | |||

| − | 125 000 spheres were generated in a cubical volume, and fell down in the graivty. The calculation took three days, and is available here in two versions - small and big. |

||

| − | |||

| − | [http://yade.berlios.de/content/06-videos______/125k_sm.avi download 2.2 MB >>] |

||

{{clr}} |

{{clr}} |

||

Latest revision as of 14:40, 25 July 2014

If you are working with yade, please upload some of your screenshots to show others your work!

Videos

If you click on one of the following links, you will be redirected to a page that contains the videos:

- Outflows

- Ball mill

- Representing surfaces beams wires

- Fluid-solid coupling

- Processing machines

- Miscellaneous videos

Screenshots

Uniaxial tension/compression test

This example can be found in examples/concrete/uniax.py

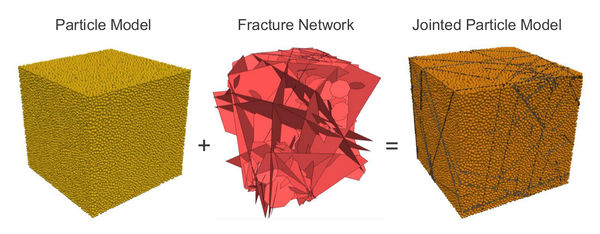

Jointed/Fractured Media

YADE can be used to model media containing pre-existing fractures/discontinuities. The module was initially developed for the study of fractured rock masses as described in refs [1], [2] and [3].

Discrete fracture network (DFN) can be imported as meshed surfaces and embeded into a predefined intact medium consisting of bonded particles. Interactions located across a discontinuity surface are identified and their behavior can be adjusted according to the user's choice (cohesive, frictional,...). An option provides the possibility to orientate the contact geometry in agreement with the discontinuity surface to get rid of the particle shape (for more details, see refs [1], [2] and [3]). An example showing how to use this module is provided in example/jointedCohesiveFrictionalPM/

[1] http://dx.doi.org/10.1016/j.jmps.2011.01.009

[2] http://dx.doi.org/10.1016/j.ijrmms.2012.02.009

[3] http://dx.doi.org/10.1111/j.1365-246X.2012.05642.x

Other

Yade is now (2007) good enough to produce some results. Those results are at first compared with results from other numerical computations software, then with real-world experiments. Several articles are planned to be written about it. For now you can have a short glance at what kind of results we can produce so far. Bear in mind that this is just a quick look at screenshots and nothing more.